The Lengths We Go To In Wetsuit Sustainability

Rip Curl is dedicated to crafting high-quality, enduring, resilient products.

As a Certified B Corporation (B Corp), we are dedicated to ensuring you can purchase the best products on the market with the confidence that they are made with a commitment to minimising environmental impact.

- Rip Curl is on a journey to do things better, with less impact

- We have ambitious ESG goals, including specific targets for responsible materials

- Rip Curl and our wetsuit factory OnSmooth Thailand are proud to be Certified B Corp

- We own and operate Onsmooth, and our Thai Crew are paid a living wage

- We used natural rubber across over a third of our wetsuits this year, with a target of over half next year

- We have an industry-leading Service and Repairs offering, that aims to maintain and extend the life of a wetsuit – last year alone we repaired over 10,000 wetsuits

- When we can’t extend a wetsuits life, we take it (any brand, not just Rip Curl) and recycle it through our global Recycle Your Wetsuit program available in Australia, Europe, and North America – we’ve recycled over 25,000 wetsuits to date

- We also recycle and upcycle production waste, and the post-production waste of old wetsuits, into carpet underlay

Responsible sourcing and manufacturing have been an evolving path for us as we strive to do things better without compromising quality, performance or the environment. With our brand-owned wetsuit manufacturing facility – and Certified B Corp in its own right - Onsmooth, Rip Curl is a vertical manufacturer of wetsuits. This allows us to have direct ownership of the various stages of production rather than relying on external suppliers. We’re proud that our factory in Chiang Mai was the second Certified B Corp facility in Thailand. We’re on the Search to reduce our impact from integrated solar and waste management through to new standards in environmental social governance as a commitment to our crew.

We’ve identified that doing things responsibly in our industry is multi-tiered, and there is no single solution to producing sustainable products and reducing our impact. Sustainability is not achieved at one point but is the sum of all the gains made along the way.

It starts with responsible sourcing and manufacturing.

We’re proud to be a Certified B Corp

Rip Curl is a Certified B Corp and gained certification in 2023. B Corps are businesses that meet high standards of social and environmental performance, accountability, and transparency. Certification means that Rip Curl has been verified as meeting these high standards by B Lab (a global independent body) and that we have made a legal commitment to stakeholder governance and demonstrating accountability through transparency.

Though we’re proud to be a B Corp, our journey to doing things better, with less impact, started long before this.

Here are some of the lengths we go to:

We Use Responsible Rubber

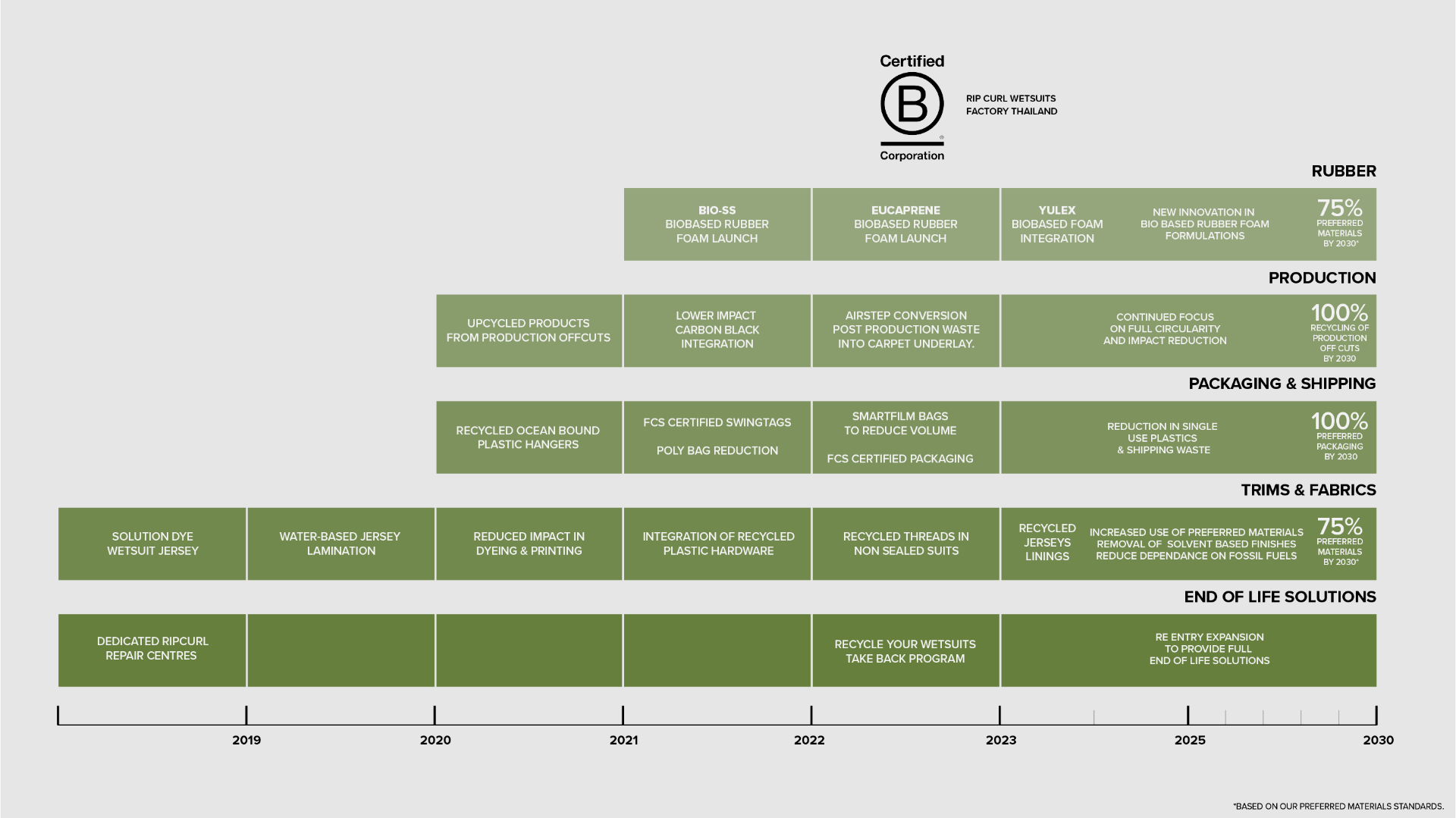

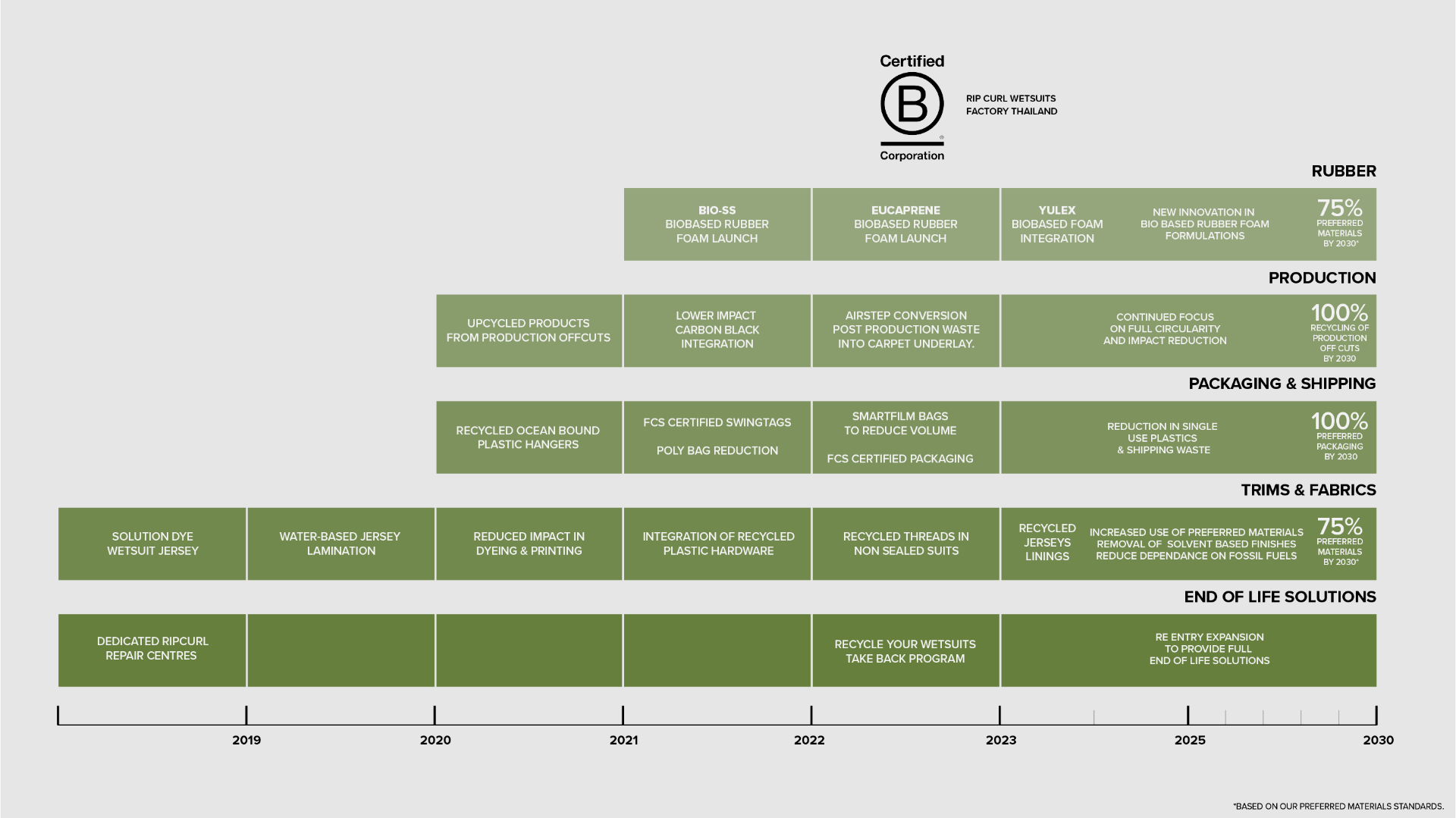

In 2021 we introduced BIO SS rubber, which utilises natural rubber, softeners, and powdered oyster shells as renewable fillers. BIO SS rubber meets the elongation, thermal performance, and durability we demand from our products to help reduce the environmental impact of traditional petrochemical-based neoprene.

In 2022, we adopted Eucaprene rubber, which uses eucalyptus oil and recycled oyster shell powder to further reduce the impact of the foam.

We manufacture using Yulex natural rubber harvested from rubber trees, which is plant-based and latex-allergy friendly. It’s a responsible alternative to chloroprene and replaces over 60% of the foam formula.

It doesn’t stop here. Our journey with preferred materials is ever-evolving as we constantly refine new plant based foam formulations and search for alternative ingredients such as Oyster shell and Soybean to further improve the end product. For 2024 – 25 our new foam formulations will be sourced from more than 70% of bio-based content.

We’ve achieved a marked increase in natural rubber throughout out wetsuits from 16% in FY23 to 25% of the product ordered for FY24.

Rip Curl Owned Factory & Production

Since 1989, Rip Curl has owned and operated the wetsuit manufacturing facility Onsmooth in Chiang Mai, which in 2023 became the second Certified B Corp facility in Thailand. Operating this facility allows us to control the environmental impact of wetsuit production, as well as pricing, lead times and entitlements for our workers, all while allowing us to develop the ultimate wetsuits.

We foster and nurture the social element by paying a living wage and encouraging our crew to be part of community clubs. Our factory is one of the several Rip Curl-occupied sites where we’ve installed solar panels to create renewable energy to reduce our consumption of power and electricity. In 2021 and 2022 we offset 100 per cent of our operational emissions, and about 130 tonnes of offcuts from the wetsuit factory were diverted from landfill to make carpet underlay.

Since 2008, we’ve been upcycling production waste and old wetsuits into new materials for footwear, coolers and padding for backpacks. We reduce our waste, optimising the use of our materials by ensuring that our production lay markers are optimising the use of the materials within our products. We collaborate with our partner Airstep to convert the neoprene waste into new carpet underlay materials that would otherwise go into landfill. Our suppliers reduce CO2 emissions by up to 90% in the production of lower impact carbon black over traditional virgin carbon black used in wetsuit foam. Lower impact carbon black is recovered through pyrolysis processing of used car tyres and we’re in collaboration to use old disused wetsuits and waste neoprene materials to produce lower impact carbon black.

Product Finishes

We use water-based laminations to reduce the amount of volatile organic compounds emitted as harmful gases from solvent-based adhesives. Using recycled jerseys rather than virgin polyester minimises the impact on precious production resources and reduces our reliance on fossil fuels. Our material suppliers save up to 60% of our water consumption by using a water-saving dyeing machine rather than traditional water dyeing methods. 50% of the water used in the dyeing process can be reused in the process with our new wastewater treatment. By utilising digital printing for all multi-colour prints and yardages, production waste is further reduced. Additionally, we use solution dyeing to save energy and conserve water and to improve our products’ colourfastness and resistance to fading.

From Factory To Warehouse

As part of our Search to do things better across the board, we’re on a journey to reduce the amount of waste through shipping our goods and the use of plastic. We know this is an area with a huge environmental impact and that’s why we have a strong commitment to implement more and better sustainable practices. By reducing the physical size and eliminating polybags from our largest volume colourways to Australia, we have made significant reductions in plastic waste. Through implementing new smart film with BDP additive, we’ve been able to further reduce our material volume of plastic by 40% across all wetsuit production for Rip Curl

All our swing tag packaging is produced utilising paper and car stock certified by The Forest Stewardship Council (FSC) as part of our responsible sourcing strategy. We've ditched the traditional little plastic Kimble tag commonly found on swing tags and all wetsuit hangers are currently made from recycled ocean-bound plastics. We aim to update these hangers to 80% recycled polymers in a construction that is both durable and capable of 100% domestic recycling.

End-Of-Life Solutions – So Where Does It End Up?

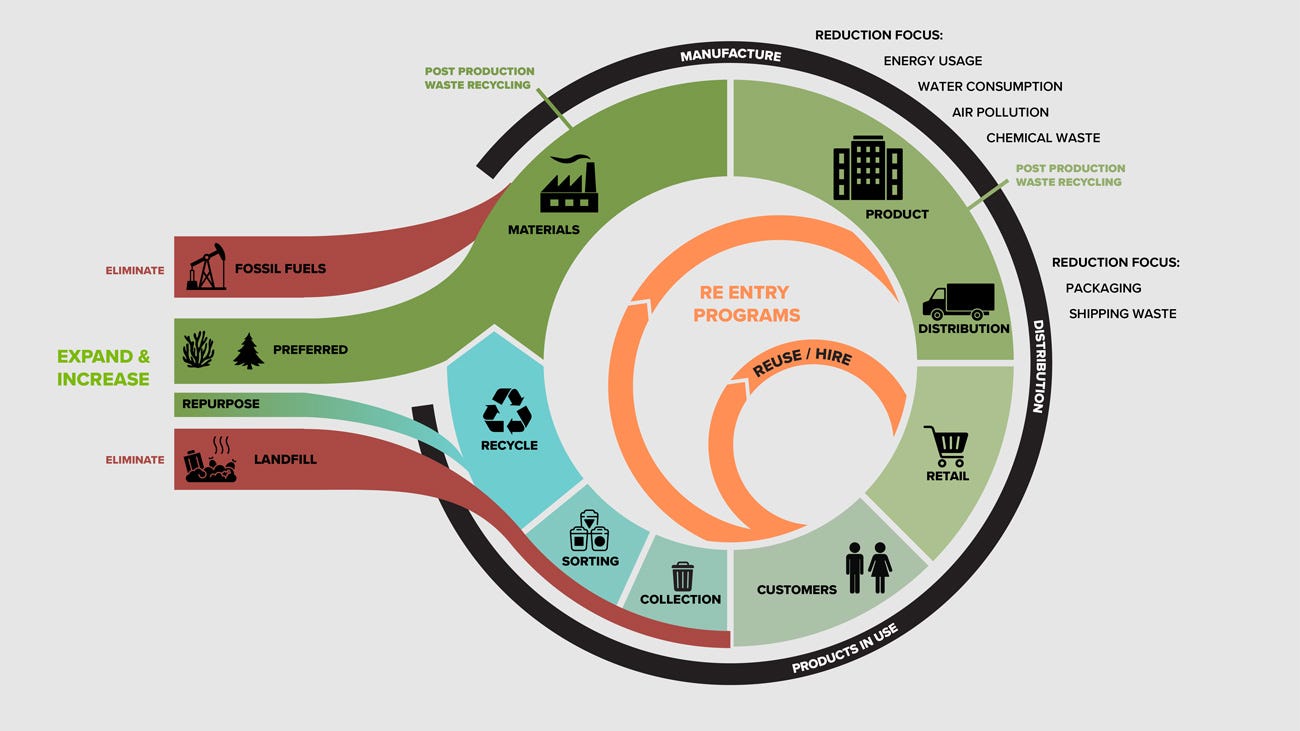

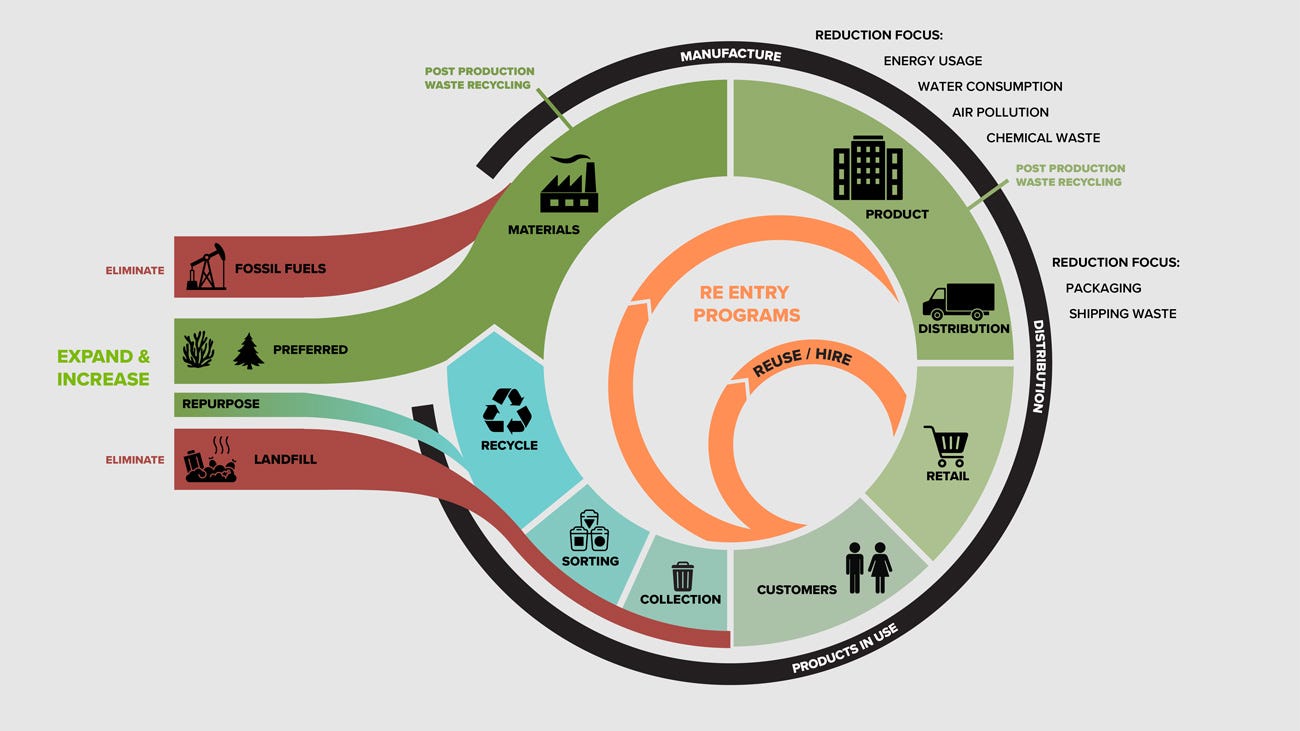

We’re committed to innovations in circularity and are working to bring you a full end-of-life solution for Rip Curl wetsuits. ReEntry is a series of initiatives to drive end-of-life solutions for all products through a number of solutions with the aim to prevent products from going to landfill.

We offer a Wetsuit Take Back Programme across Australia, USA, France, Portugal, and Spain so surfers can repurpose any surf-branded wetsuit through key Rip Curl stores to produce new materials for other products and industries. So far we’ve diverted over 25,000 wetsuits from landfill.

The Wetsuit Take Back Programme will be further enhanced to recycle products to produce compounds such as carbon black used in the production of new wetsuit materials.

We support our customers of Rip Curl wetsuits with our industry-leading Service and Repair centres to maintain and extend the life of our suits.

In 2024, Rip Curl launched a new initiative in Europe to allow customers to Hire a wetsuit for a climate they’ll only be in for a short period rather than purchasing it, using it a few times, and keeping it in the garage for five years.

Sustainable production is rapidly changing with new and better ways. We always strive to do better for our crew, customers, and the environment